Building vs Launching: Common Beginner Errors

Share

When it comes to model rocketry, beginners often struggle with two distinct stages: building and launching. Each stage presents its own challenges:

- Building Errors: These are structural issues like misaligned fins, using weak adhesives, or packing the parachute incorrectly. For example, a poorly aligned fin can destabilise the rocket, while an overpacked parachute may fail to deploy.

- Launching Errors: These are operational mistakes, such as launching in high winds, using faulty igniters, or ignoring safety rules. For instance, strong winds can cause "weathercocking", where the rocket veers off course.

Understanding and addressing these mistakes is key to a safe and successful launch. Following proper assembly techniques, checking environmental conditions, and adhering to safety protocols can help avoid common pitfalls.

Key Takeaway: Build with precision, launch with caution, and always prioritise safety.

How to Attach and Fold Model Rocket Parachutes!

Mistakes Made During Building

Building errors often occur when assembly is rushed or materials that compromise the structure’s strength are used. As Rocketry for Schools points out:

"When building model rocket kits, adhesive mistakes can lead to failure during flight".

Here are some common building mistakes and how to address them to ensure your rocket stays structurally sound.

Misaligned Fins

Misaligned fins are one of the most frequent issues and can severely affect flight stability. Even a slight misalignment can cause the rocket to spiral or drift off course during its ascent. The fix? Use fin alignment guides. These tools make sure every fin is positioned at the right angle and evenly spaced around the rocket’s body tube. Symmetry is key for a smooth flight. For an even better fit and improved aerodynamics, sand the fins before attaching them.

Poor Adhesive Choices

Choosing the wrong adhesive can compromise the rocket’s entire structure. For example, hot glue is unsuitable for critical components like fins as it doesn’t handle flight stresses well. This can lead to disastrous results:

"Otherwise, the rocket is structurally weak, and is a disaster waiting to happen." - Apogee Rockets.

Instead, opt for adhesives specifically designed for rocketry. Wood glue is a reliable option for balsa fins, while specialised adhesives recommended by Rocketry for Schools work well for bonding materials like cardboard and plastic.

Improper Parachute Packing

Parachute deployment issues are often traced back to how the parachute is packed during assembly. A common mistake is making the nose cone too tight. If the ejection charge fires and the nose cone doesn’t release, the engine could be expelled instead, leading to a failed recovery. The solution? Ensure the nose cone is snug enough to remain secure during flight but loose enough to be easily ejected by the charge.

Mistakes Made During Launching

While flaws in construction can weaken a rocket's durability, errors during launch can severely compromise its safety. Even a rocket built to perfection can fail - or worse, cause harm - if proper launch procedures aren’t followed. Just as building mistakes can undermine a rocket’s structure, launch errors can disrupt its ability to fly safely and predictably. Below are some of the most common mistakes made at the launch pad, particularly by beginners.

Launching in High Winds

Wind is a major hazard for successful rocket launches. When wind speeds exceed safe limits, rockets can "weather-cock", tilting into the wind and veering off course unpredictably. The UKRA Safety Code provides clear guidance on this:

"Rockets must not be flown in winds exceeding 20mph. UKRA recommends that rockets are not flown in winds exceeding 15mph."

For wind speeds above 10mph, choose a motor that ensures stable flight while the rocket is still supported by the launch rail. High winds also increase the likelihood of your rocket drifting during recovery, potentially landing in trees, near power lines, or in inaccessible areas. Always check wind conditions not just at ground level but at the altitude your rocket is expected to reach.

Faulty Igniters and Connections

After wind-related risks, technical setup issues are another common cause of launch failures. One frequent error is connecting igniters while the launch controller remains powered, which can lead to accidental ignition right at the pad. To prevent this, always use an electrical launch controller equipped with a removable safety key and a momentary launch button. Insert the safety key only after ensuring everyone has cleared the launch area.

In the event of a misfire, immediately remove the safety key and wait before approaching the rocket. For low-power rockets, wait at least one minute; for high-power rockets, wait three minutes. Using reliable equipment, such as the igniter controllers from Rocketry for Schools, can help ensure safe and consistent ignition.

Ignoring Safety Codes

Disregarding safety rules puts everyone at risk. NASA emphasises this point:

"If you follow the rules, model rockets are as safe as any other toy. But if you break the rules, you endanger yourself and those around you."

In the UK, compliance with the UKRA Safety Code is mandatory. This includes observing a five-second countdown, maintaining safe distances based on motor impulse, and ensuring your launch rail is positioned within 20° of vertical. If your rocket is expected to exceed 120 metres (400 feet) in altitude, you’ll need to notify the CAA by submitting a Notice to Airmen (NOTAM) at least 28 days in advance. Additionally, the Range Safety Officer (RSO) has the authority to delay or cancel any launch deemed unsafe.

sbb-itb-f093e97

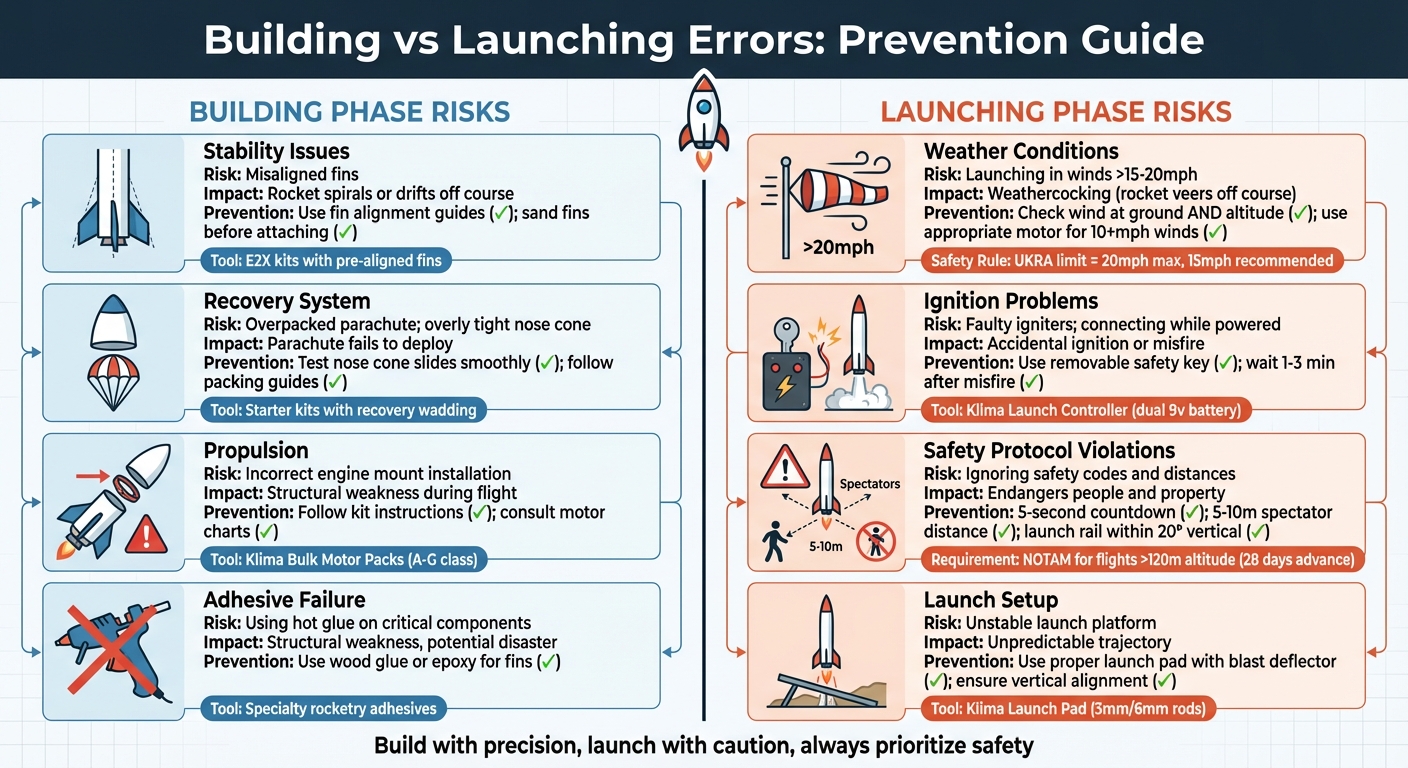

Building vs Launching Errors: Side-by-Side Comparison

Building vs Launching Errors in Model Rocketry: Common Mistakes and Prevention Guide

Understanding the difference between structural issues and launch mishaps is crucial for addressing problems effectively. Building errors are all about the rocket's physical structure - they affect its integrity long before it even gets close to the launch pad. On the other hand, launching errors occur during the flight phase, often caused by operational missteps or external factors like weather conditions.

This comparison brings clarity to the risks involved in each phase. For instance, poorly aligned fins can destabilise a rocket no matter the conditions, while strong winds might cause a perfectly built rocket to veer off course (a phenomenon known as weathercocking). By focusing on careful assembly and following strict launch protocols, many of these issues can be avoided.

Here’s a side-by-side look at the key risks, along with preventative measures and recommended tools to help ensure smooth launches.

Comparison Table

| Error Category | Building Phase Risk | Launching Phase Risk | Prevention Tips | Recommended Products |

|---|---|---|---|---|

| Stability | Misaligned fins | Weathercocking in strong winds | Use alignment jigs during assembly and always check wind conditions before launch. | E2X kits with pre-aligned fins; Klima Launch Pad |

| Recovery System | Overpacked parachute; overly tight nose cone | Parachute fails to deploy or deploys too late | Test the nose cone to ensure it slides out smoothly and follow proper parachute packing guides. | Starter kits with recovery wadding included |

| Propulsion | Incorrect engine mount installation | Using engines with too much or too little power | Follow kit instructions carefully and consult motor charts to select the appropriate engine. | Klima Bulk Motor Packs (A-G class motors) |

| Ignition | Weak adhesive on structural parts | Faulty connections or igniter failure | Use wood glue or epoxy instead of hot glue, and double-check all igniter connections. | Klima Launch Controller with dual 9v battery capacity |

| Safety | Adding metal parts or modifying engines | Ignoring safety distances or site rules | Stick to non-metal parts and maintain a safe distance of 5–10 metres for spectators. | Sky Piercer Starter Set |

How Rocketry for Schools Products Prevent Common Mistakes

The right tools can mean the difference between a successful rocket launch and a frustrating failure. Rocketry for Schools provides products specifically designed to help beginners sidestep common issues during both the building and launching stages. Let’s explore how these products address typical challenges.

Starter Sets Minimise Building Errors

Starter kits like the Sky Piercer Starter Set (£84.95) are thoughtfully curated with pre-selected materials - such as cardboard tubes, balsa wood, and plastic fins - and come with detailed, step-by-step instructions. These kits are designed to prevent structural mistakes and avoid rushed assembly. They also include educational guides that highlight adhesive errors many beginners make. A standout feature is the pre-assembled engines, which eliminate the risks associated with DIY engine construction. Plus, all components are carefully designed to stay within the safe weight limit of 53 ounces.

Team Class Packs for Safe Group Launches

For group activities, Rocketry for Schools offers team class packs like the 10x Star Chaser Team Class Pack (£79.45) and 5x Star Chaser Team Class Pack (£39.95). These packs provide everything needed for a uniform and safe experience, including rockets, motors, launch pads, controllers, batteries, and wadding. By standardising materials and equipment, these bundles ensure no critical components are forgotten, enhancing both safety and performance. This consistency is particularly important for teaching environments, where safety is a top priority.

Reliable Accessories for Smooth Launches

Rocketry for Schools doesn’t just stop at building kits - they also tackle common launch issues with high-quality accessories.

- Klima Launch Controllers are equipped with dual PP3 9v batteries, offering consistent ignition power and reducing the likelihood of misfires that can occur with single-battery setups. These controllers also feature safety key systems and momentary launch buttons that cut the circuit when released, adding an extra layer of safety.

- Klima Launch Pads are designed to accommodate 3mm or 6mm launch rods as well as launch rails, providing a stable platform for rockets of different sizes. The included blast deflectors shield ground equipment from exhaust gases, while the launch rods ensure rockets maintain a trajectory within 20° of vertical, aligning with UKRA safety guidelines.

These thoughtfully designed products help aspiring rocketeers avoid common mistakes, making the process safer and more enjoyable for everyone involved.

Conclusion

Let’s take a moment to reflect on the key lessons that enhance safety and success in rocket launches. Understanding the difference between building and launching errors is crucial for ensuring a smooth flight. Issues during the building phase - like misaligned fins or choosing the wrong adhesive - can weaken your rocket’s structure before it even takes off. On the other hand, launching mistakes, such as ignoring wind conditions or neglecting safety protocols, pose risks to both people and equipment. As NASA wisely states: "If you follow the rules, model rockets are as safe as any other toy. But if you break the rules, you endanger yourself and those around you".

Safety is non-negotiable in both the building and launching stages. Properly balanced rockets, avoiding launches in high winds, and sticking to clear countdown procedures are all essential steps to minimise risks.

Rocketry for Schools supports safer launches by providing starter kits, dependable launch controllers, and team class packs. These resources help standardise equipment, making group launches not only safer but also more enjoyable.

FAQs

How can I ensure rocket fins are properly aligned during assembly?

When assembling a rocket, getting the fins aligned properly is key to ensuring a stable flight. Tools like fin alignment jigs are incredibly useful for this task. These jigs hold the fins in place during assembly, making it easier to position them evenly and accurately. By doing so, they improve the rocket’s balance and overall flight stability. For instance, a jig can keep the fins steady while the adhesive dries, reducing the risk of any misalignment.

Before attaching the fins, it’s a good idea to inspect them closely. Check that they are straight and uniformly shaped. Sanding the edges and test-fitting them beforehand can help achieve a snug, precise fit. Misaligned fins can lead to instability or cause the rocket to veer off course, so taking the time to get this step right is essential for a successful launch.

By combining the use of a fin alignment jig with careful preparation and inspection, you’ll make the assembly process smoother and greatly improve the chances of a steady, reliable flight.

What steps should I take to safely launch a rocket in windy conditions?

To ensure a safe rocket launch in windy conditions, begin by checking the wind speed at around 2 metres above ground using a handheld anemometer. If gusts exceed 10 mph, it’s best to postpone the launch, as stronger winds can cause unpredictable flight patterns. While the UKRA guidelines allow for a maximum wind speed of 20 mph, calmer conditions - ideally under 10 mph - offer much better control.

Another important step is to adjust your rocket’s launch angle slightly into the wind to account for potential drift. Always stick to the safety protocols provided in your rocket kit’s instructions. These measures are key to achieving a safer and more controlled launch.

What can I do if my rocket’s parachute doesn’t deploy?

If your rocket’s parachute fails to deploy, it’s essential to troubleshoot the recovery system before your next attempt. Start by examining the parachute itself - make sure it’s packed correctly, undamaged, and ready for deployment. Check that the ejection charge is set up properly and that all components, like the shock cord and deployment mechanism, are securely in place and functioning as they should.

Should the problem continue, take a closer look for any tears in the parachute or signs of improper folding. You might also want to try a slightly larger or sturdier parachute to enhance its reliability. Always stick to safety protocols and thoroughly inspect your rocket’s build and upkeep to reduce the chances of deployment issues in future launches.