Why Temperature Affects Rocket Motor Efficiency

Share

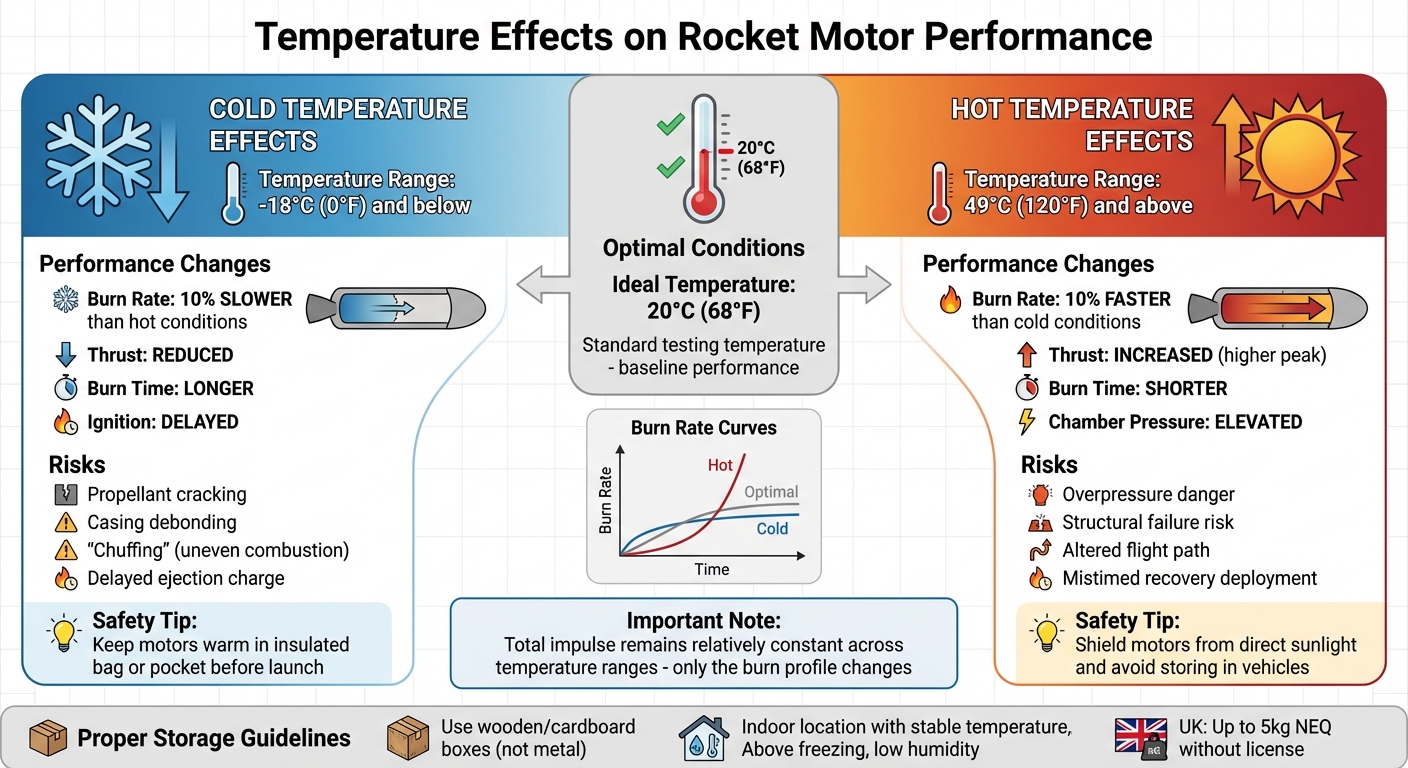

Temperature directly impacts how rocket motors perform by altering the burn rate, thrust, and pressure. Warmer conditions make propellants burn faster, increasing thrust but risking overpressure. Cold conditions slow the burn rate, reducing thrust and causing ignition issues. Motors are designed to work best near 20°C, but deviations can lead to safety risks and performance changes. Key takeaways:

- Hot weather: Faster burn rate, higher thrust, shorter burn time, risk of overpressure.

- Cold weather: Slower burn rate, reduced thrust, ignition problems, potential for propellant cracking.

- Storage: Keep motors in stable, moderate temperatures. Avoid direct sunlight or freezing conditions.

- Launch prep: Insulate motors in cold weather and shield from heat in hot conditions.

Managing temperature ensures reliable and safe motor performance during launches.

How Temperature Affects Rocket Motor Performance: Hot vs Cold Conditions

What Role Does The Ideal Gas Law Play In Rocket Propulsion? - Chemistry For Everyone

How Temperature Affects Propellant Combustion

The starting temperature of rocket propellant plays a critical role in how it burns. When the propellant's temperature is higher, less energy is needed to ignite it. This initial condition directly influences the speed of combustion and, as a result, the propellant's overall performance. Faster combustion generates more gas per second, which increases thrust. On the other hand, lower temperatures slow down the burn rate, leading to reduced pressure and thrust.

The Link Between Temperature and Burn Rate

"The effect of the solid propellant's initial temperature on its burning rate has long been recognised. This effect causes variations in the pressure, thrust, and burning time of solid propellant propulsion systems."

The extent to which temperature affects the burn rate depends on the propellant's composition. For example, in composite propellants, factors like the size and distribution of oxidiser particles significantly influence how temperature changes impact performance. In hypergolic propellants, even a modest 10°C change in reactant temperature can result in about a 0.1% shift in specific impulse. Additionally, higher chamber pressures tend to slightly reduce the sensitivity of burn rates to temperature variations.

These changes in burn rate directly influence the energy released during combustion, which in turn affects thrust generation.

Energy Release and Thrust Variations

Temperature doesn't just alter the burn rate - it also impacts the energy output during combustion. Specifically, it affects the propellant's enthalpy, or total energy content, before ignition. A higher initial temperature increases the starting enthalpy, which leads to a higher adiabatic flame temperature during combustion. This marks the maximum temperature that can be achieved during the process.

However, when combustion temperatures rise above approximately 3,000 K, molecular dissociation becomes a factor. At such high temperatures, thermal energy breaks molecules into simpler components, using up energy that would otherwise contribute to thrust. As Richard Nakka explains in his research on experimental rocketry:

"Dissociation consumes energy that would otherwise be available for conversion to kinetic energy of the exhaust, and tends to limit the combustion temperature."

Additionally, temperature variations influence the chemical equilibrium of the combustion reaction. This alters the composition of the exhaust gases, affecting properties like the specific heat ratio and molecular weight of the exhaust. These changes directly impact how efficiently the nozzle converts thermal energy into thrust.

Effects of Cold and Hot Temperatures on Rocket Motor Performance

Extreme temperatures can significantly impact rocket motor performance, altering thrust and posing potential safety risks. Both cold and hot conditions create unique challenges that affect how motors function during flight.

Cold Temperatures: Slower Burn Rates and Performance Issues

In cold conditions, the propellant burns more slowly, which reduces the flow of hot gases through the nozzle. As NASA puts it:

"The thrust of any engine depends on how fast and how much hot gas exhaust passes through the nozzle."

When the burn rate slows, both the mass flow rate and the exhaust velocity drop, resulting in reduced thrust.

Ammonium Perchlorate Composite Propellant (APCP) motors are particularly sensitive to the cold. They may experience "chuffing", which is a pulsing, uneven combustion instead of a steady burn. Motors that have been exposed to prolonged cold, known as "cold-soaked", often take longer to ignite and can delay the firing of the ejection charge. Additionally, extreme cold or repeated temperature fluctuations can cause the propellant to crack or separate from the casing - a process called debonding. This can lead to dangerous pressure spikes when the motor is ignited.

While cold conditions slow things down, high temperatures introduce a different set of risks that compromise motor integrity.

High Temperatures: Increased Pressure and Structural Risks

High temperatures speed up the propellant burn rate, which shortens the burn time and increases chamber pressure. This rise in pressure can push the motor closer to its structural limits, risking potential failure.

Heat absorption is another concern. Rocket motor cases left in direct sunlight, especially in hot weather, can become dangerously warm. This "heat-soaking" effect is a particular risk when motors are stored in car boots or left exposed at launch sites. The result? A faster burn rate, higher peak thrust over a shorter time, and altered charge timing.

Interestingly, despite these changes in burn rate and thrust profile, the total impulse - essentially the motor's total energy output - remains relatively consistent across a wide temperature range. However, these shifts in performance can cause deviations in the rocket's flight path and lead to poorly timed deployment of recovery systems.

sbb-itb-f093e97

Standard Testing Temperatures for Model Rocket Motors

Model rocket motors are typically tested and certified at a standard temperature of around 20°C (68°F). This temperature serves as a baseline because the initial temperature of the propellant plays a key role in determining the motor's performance.

The National Association of Rocketry (NAR) sets these standards and oversees testing to ensure both safety and consistency. Their carefully regulated testing protocols allow manufacturers to provide accurate performance data, such as time-averaged thrust and total impulse. These metrics are essential for categorising engines into classes like A, B, or C. By maintaining controlled testing conditions, the thrust profile - determined by how the flame front moves through the propellant - remains consistent. This ensures that the certification data provided by NAR matches the motor's expected performance under standard conditions. These standardised results also serve as a reference point for adjusting motor performance based on launch-day temperatures, a topic explored further in later sections.

Of course, not every launch will take place in ideal 20°C conditions. Research has shown that motors stored at extreme temperatures can behave quite differently. For example, motors kept at -18°C (0°F) may burn up to 10% slower than those stored at 49°C (120°F). This variation means that a motor's actual performance on launch day might not align perfectly with its certified specifications. By understanding these testing standards, you can better predict how motors will react in extreme heat or cold - whether it’s avoiding overpressure risks in hot weather or compensating for lower thrust in colder conditions. These insights lay the groundwork for the practical temperature management tips covered in the next sections.

Practical Tips for Temperature Management in Model Rocketry

Keeping your rocket motor at the right temperature is crucial to ensure it performs as expected, no matter the weather.

Storing Rocket Motors at Safe Temperatures

Proper storage is key to maintaining the integrity of your rocket motor's propellant. Fluctuating temperatures, especially freeze/thaw cycles, can damage the propellant by causing cracks, which might lead to motor failure.

To minimise risks, store motors in wooden or cardboard boxes rather than metal ones, as metal transfers heat more quickly. Choose an indoor location with stable temperatures well above freezing and low humidity. Under the UK Explosives Regulations 2014, you can store up to 5kg of NEQ (Net Explosive Quantity) without a licence, as long as motors (hazard type 3 or 4) are kept in a single, secure location. If a motor has been dropped or exposed to freezing conditions, it’s safest to submerge it in water for disposal.

Preparing for Launch in Cold or Hot Weather

Storage is just the first step - on launch day, you’ll need to adjust your handling based on the weather. In cold conditions, keeping motors warm until launch is crucial. You can do this by placing them in an insulated bag or even carrying them in a pocket. This prevents the motors from becoming too cold, which can slow the burn rate and make ignition harder, particularly for APCP (Ammonium Perchlorate Composite Propellant) motors.

In hot weather, avoid exposing motors to direct sunlight or leaving them in a vehicle, as black casings absorb heat quickly. Extreme heat can accelerate the burn rate, affecting performance.

Interestingly, while temperature changes affect the burn rate, the total impulse of the motor stays almost the same. A cold motor will burn more slowly, producing lower thrust over a longer period, whereas a hot motor burns faster, delivering higher thrust in a shorter time. Keep this in mind when adjusting flight predictions, especially for recovery system delay timings.

Using Insulation and Other Protective Measures

For longer events or extended launch days, consider using extra insulation to keep motors at a steady temperature. An insulated cooler can help maintain a moderate temperature throughout the day. Adding internal insulation, such as layered paper or resin coatings, can further reduce heat transfer. Foam padding inside storage containers is another good idea, as it not only helps with temperature control but also provides added protection against impacts .

Conclusion

Temperature plays a key role in rocket motor performance, directly affecting burn rate, thrust, and structural integrity. Managing temperature effectively is essential for both optimal performance and safety. In freezing conditions, propellants can crack, or the motor casing may debond, while excessive heat can lead to overpressure and even motor failure.

To address these challenges, it's important to store rocket motors in stable, indoor environments, away from extreme temperatures. On launch day, keep motors warm during cold weather and shield them from direct sunlight in hot conditions. Since propellants have low thermal conductivity, always allow enough time for the motor's temperature to equalise before use.

FAQs

How does temperature influence the burn rate of rocket propellants?

Temperature is a key factor in how quickly rocket propellants burn. When temperatures rise, the chemical reactions at the surface of the propellant speed up, causing it to burn faster and consume the propellant grain more quickly. On the other hand, colder temperatures slow these reactions, leading to a reduced burn rate.

This temperature dependence makes proper storage and handling of rocket motors essential for maintaining consistent performance. For those involved in rocket projects, particularly in educational environments, being aware of these effects can lead to more predictable flight outcomes and help fine-tune your designs for better results.

What challenges do rockets face when launched in extreme temperatures?

Launching rockets in extreme temperatures presents a host of challenges. When exposed to high heat, the materials used in the rocket motor can deteriorate. For instance, epoxy resins might start to boil off or even char, which compromises the motor's structural strength. On top of that, the propellant inside the motor could begin to chemically break down, raising the risk of spontaneous ignition or, in the worst-case scenario, a rupture.

Cold conditions bring their own set of problems. The propellant can lose efficiency or struggle to ignite properly, which directly impacts the rocket's performance. These temperature-related issues aren't just about performance - they're serious safety concerns too. That's why maintaining rockets within their recommended temperature ranges during storage and launch is absolutely critical for both safety and performance.

How should I store rocket motors to avoid temperature-related problems?

To ensure rocket motors stay safe and function effectively, it's crucial to store them in a cool, dry location with stable temperatures. Keep them away from heat sources, direct sunlight, or areas where temperatures can swing dramatically, like garages or lofts. Always aim to keep the storage temperature well below the maximum limit specified by the manufacturer.

Exposing rocket motors to fluctuating or high temperatures can lead to chemical breakdown, which could impact their performance or even pose safety hazards. By sticking to consistent storage conditions, you can preserve their reliability and readiness for use.